Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

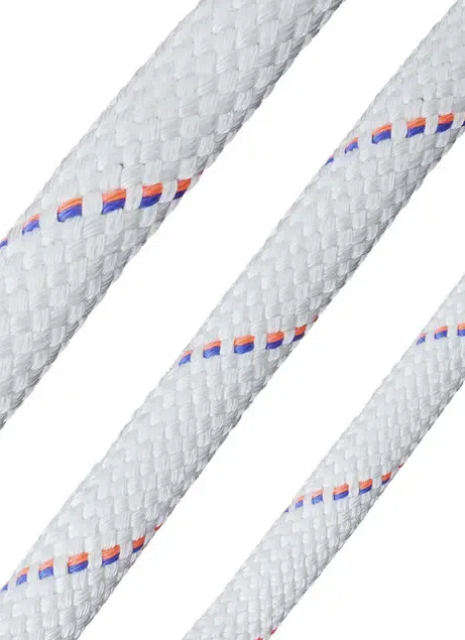

Regular care is the difference between a rope that serves reliably for years and one that fails when you need it most. At Xinglun Rope Cable Co., Ltd, we understand that a marine rope is more than just a piece of gear—it is a safeguard for your vessel and crew. Proper rope maintenance ensures durability, protects your investment, and minimizes unexpected downtime at sea. This guide explains why routine care matters, how to inspect, clean, and store ropes, and when to replace them, giving boat owners and marina operators practical knowledge for long-term use.

Marine ropes work under constant stress—exposure to salt water, UV rays, and abrasive surfaces. Over time, these factors degrade fibers and compromise strength. Routine maintenance helps detect issues before they lead to failures that may cause property damage or personal injury. Economically, maintaining rope saves costs by extending service life, reducing the need for frequent replacements. It also contributes to operational efficiency: crews spend less time dealing with unexpected rope issues and more time focusing on safe navigation and port activities. A well-kept rope is not only stronger but also easier to handle, coil, and deploy under pressure.

When rope care is overlooked, problems arise quickly. Docking lines frayed by constant rubbing against bollards can snap under tension, leaving vessels adrift. Mooring ropes weakened by hidden core damage may part during storms, putting ships and port facilities at risk. Even anchor lines that appear intact can lose strength if mildew or UV damage has gone unchecked. Each of these incidents can be prevented with consistent inspection and upkeep. Beyond immediate danger, such failures may also damage a company’s reputation for safety and reliability, which is why professional operators emphasize maintenance as a key part of maritime management.

Systematic inspection is the foundation of rope maintenance. A step-by-step approach ensures no warning sign is overlooked. Experienced operators often check their ropes before and after every major use, while commercial vessels follow stricter inspection routines.

Start by examining the rope’s outer layer. Look for areas where fibers appear fuzzy, flattened, or discolored. On double-braid or jacketed ropes, worn sheaths indicate that the protective cover has thinned and the core may soon be exposed. Even minor chafe can grow into a weak point under load, so early detection is crucial.

After the surface, run your hands along the rope to feel for inconsistencies. A healthy rope has uniform firmness. Soft spots or uneven thickness suggest internal fiber damage, usually from shock loads or prolonged bending around tight radii. Once the core integrity is compromised, strength is reduced significantly.

Marine ropes constantly face sunlight. Ultraviolet rays weaken synthetic fibers, leading to bleaching, fading, and brittleness. If the rope feels stiff, powdery, or shows cracked strands, UV degradation is present. For natural fiber ropes, broken fibers and loss of flexibility are early signs of structural weakness.

A rope’s environment often exposes it to salt, sand, and biological growth. Regular cleaning keeps fibers strong and prevents contaminants from accelerating wear. Proper cleaning also improves handling comfort—dirty ropes tend to stiffen and abrade hands faster.

The simplest method is rinsing thoroughly with fresh water to remove salt crystals and debris. For ropes with oil stains or heavy dirt, use a mild detergent diluted in water. Harsh chemicals or bleach should be avoided, as they weaken fibers and compromise safety. Ropes can be washed by hand in a bucket or using a front-loading washing machine on a gentle cycle. For commercial fleets, setting up a scheduled cleaning program ensures ropes are not forgotten until problems occur.

Once washed, ropes must be dried completely. Spread them loosely in a shaded, well-ventilated area. Direct sunlight accelerates UV damage, while confined storage encourages mildew growth. Never dry ropes on heated surfaces or near open flames, as high heat can melt or warp synthetic fibers. Ensuring proper drying is one of the simplest ways to extend service life. If the rope must be stored before being completely dry, make sure airflow is continuous to avoid trapped moisture, which can silently weaken fibers over time.

Not every rope showing wear must be discarded immediately. Knowing when repair is acceptable and when replacement is the only safe option is an essential part of rope maintenance.

If only the rope’s ends are frayed, trimming and applying a professional splice or whipping restores usability. Similarly, if the damage is localized near the end and the rope length allows, cutting off the weakened portion may extend service life. Many boat owners rely on splicing to create secure loops or join sections, provided the main body of the rope remains sound. In routine marina operations, such splicing solutions reduce waste and give crews flexible options for line management.

Replace any marine rope that shows multiple weak points, severe core damage, or widespread UV degradation. If inspection reveals flattening, glazing from friction, or stiffness from chemical exposure, it is no longer safe for critical applications. Safety thresholds should always lean on caution: if in doubt, replace. The cost of a new rope is minimal compared to the risks of catastrophic failure at sea. Professional operators often keep a record of load history and rope usage hours to decide on replacement timing more objectively.

Good storage practices are as important as cleaning and inspection. Properly handled ropes stay organized, maintain flexibility, and remain ready for use.

Coil ropes neatly to avoid kinks and tangles. Store them in a dry, cool place, away from direct sunlight and chemicals. For commercial fleets, tagging ropes with service dates and inspection records helps track their lifecycle. Organized storage systems save time during operations and ensure ropes are used in rotation for balanced wear. Keeping ropes off damp floors and away from sharp edges prevents silent damage that may only show later under heavy loads.

End-of-life does not mean waste. Natural fiber ropes such as manila or sisal can decompose naturally. Synthetic ropes, on the other hand, may be recycled into plastic products or repurposed for non-critical applications. Eco-conscious disposal prevents marine pollution and aligns with sustainability goals. At Xinglun Rope, we support responsible rope use, encouraging clients to adopt recycling programs wherever possible. Our innovation in materials and processes also reflects this vision, combining strength with eco-friendliness.

A marine rope is not just a tool—it is essential safety equipment. Regular rope maintenance through inspection, cleaning, proper storage, and timely replacement extends rope life and ensures reliable performance when it matters most. At Xinglun Rope Cable Co., Ltd, our ropes are engineered for strength and durability, but they perform best when cared for correctly. For commercial fleets, weekly inspections are recommended; for heavy recreational use, monthly checks suffice; and for seasonal boats, a thorough pre- and post-season inspection keeps ropes in top condition. Choosing high-quality ropes is the first step, but maintaining them completes the safety circle. If you are ready to equip your vessel with high-performance ropesdesigned to last, contact us today to learn more about our marine solutions.