Views: 0 Author: Site Editor Publish Time: 2025-05-10 Origin: Site

Mooring ropes play a crucial role in ensuring the safety and stability of vessels in a wide range of maritime environments. Whether it’s for securing a ship to a dock, anchoring a boat, or performing various maritime operations, the quality of the mooring rope used is of paramount importance. The strength, durability, and reliability of these ropes are essential to prevent accidents and ensure smooth docking and anchoring. In this blog, we will explore the process behind the creation of high-quality mooring ropes, focusing on material selection, design techniques, manufacturing processes, and eco-friendly innovations that make them stronger, more durable, and sustainable.

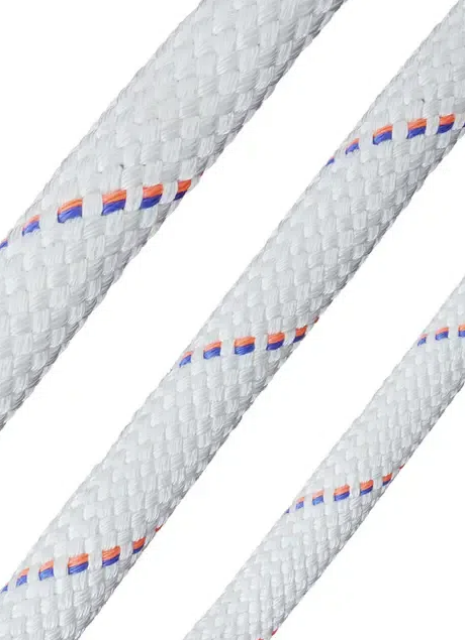

Mooring ropes are engineered to withstand the toughest marine environments. Their strength and durability are the result of careful selection of materials, sophisticated design techniques, and rigorous manufacturing processes. These ropes must be able to handle the strain of securing heavy vessels, the wear and tear from exposure to saltwater, UV rays, and the harsh marine climate. The combination of high-quality materials and specialized construction techniques allows mooring ropes to meet the highest safety standards.

The first step in creating a reliable mooring rope is choosing the right materials. Several materials are commonly used in mooring rope production, each offering distinct benefits.

Polyester: Known for its excellent abrasion resistance, polyester is one of the most widely used materials in mooring ropes. It offers minimal elongation, high tensile strength, and is resistant to UV degradation, making it ideal for marine environments.

Nylon: Nylon is a highly elastic material with excellent shock-absorbing properties, making it suitable for situations where the rope needs to absorb sudden forces or shocks. It also has good abrasion resistance and strength.

Polypropylene: While lighter than polyester and nylon, polypropylene is a more affordable material that offers good resistance to chemicals and water. However, it has lower strength compared to other materials, making it more suitable for lighter applications.

HMPE (High-Modulus Polyethylene): HMPE is a newer material known for its incredible strength-to-weight ratio. It is extremely durable and resistant to abrasion, making it a top choice for high-performance mooring ropes.

The choice of material directly affects the rope’s tensile strength, flexibility, and longevity. Polyester, for example, provides high strength and low stretch, making it ideal for secure mooring in rough seas. Nylon, on the other hand, offers superior elasticity, which is beneficial for absorbing shock loads. The material selection process ensures that the mooring rope performs as expected under varying marine conditions, providing safety and stability for vessels.

Once the material is selected, the next step is designing and braiding the rope. The construction of the rope determines its strength, torsion resistance, and flexibility.

8-strand: This design involves eight strands of fiber braided together, offering a balanced combination of strength and flexibility. It is commonly used for medium-strength mooring ropes.

12-strand: Twelve strands are woven together to create a stronger and more durable rope. This design is ideal for securing larger vessels, where higher tensile strength is required.

Double-braided: A double-braided rope features an inner core braided with an outer sheath. This design provides excellent protection against abrasion, making it particularly suitable for mooring ropes exposed to harsh conditions.

The braiding technique influences the rope’s torsion resistance (its ability to resist twisting) and its softness. For example, double-braided ropes provide better torsion resistance due to their inner core and outer sheath construction. Additionally, braided ropes are generally softer to the touch compared to twisted ropes, making them easier to handle during operations.

The manufacturing process of high-quality mooring ropes involves several crucial steps to ensure the final product meets safety and performance standards.

The first step in making a mooring rope is fiber extrusion. During this process, raw materials such as polyester, nylon, or HMPE are converted into long fibers, which are then used to make the yarns that form the rope.

Once the fibers are prepared, they are braided into the desired construction. The braiding machines intertwine the fibers to create a strong and flexible structure, depending on the chosen design (e.g., 8-strand, 12-strand, or double-braided).

After braiding, the ends of the rope are spliced to create a secure and smooth finish. Splicing helps prevent fraying and ensures that the rope remains strong and intact during use.

In some cases, the rope is set or heat-treated to enhance its strength and durability. This step involves applying heat or tension to the rope to "set" its structure and improve its performance.

Quality control is a critical part of the manufacturing process. Several tests are conducted to ensure the rope meets stringent performance standards. These tests include:

Tensile Strength Testing: To verify that the rope can withstand the required load without breaking.

Abrasion Testing: To check how well the rope can resist wear and tear when exposed to friction.

Stretch Testing: To assess the rope's ability to stretch under load, ensuring it doesn’t elongate too much during use.

In recent years, there has been a growing emphasis on making mooring ropes more environmentally friendly. Many manufacturers, including Xinglun Rope, have started incorporating recycled materials into the production of mooring ropes, such as recycled plastics. This helps reduce the environmental impact of manufacturing while still maintaining high strength and durability standards.

Eco-friendly mooring ropes are designed to provide the same level of strength and durability as traditional ropes while promoting sustainability. By using recycled materials, manufacturers are able to reduce waste and conserve natural resources, helping protect the environment without compromising on performance.

When purchasing mooring ropes, it’s essential to look for products that meet international quality standards. High-quality mooring ropes often carry certifications from reputable organizations, such as:

ISO 9001: The standard for quality management systems.

ISO 14001: Certification for environmental management systems.

ISO 45001: Occupational health and safety management.

DNV, ABS, NK, LR: These maritime certifications ensure that the rope meets the highest standards for strength, durability, and safety.

By choosing mooring ropes with these certifications, customers can be confident that they are purchasing a reliable and safe product for their maritime needs.

Mooring ropes are vital to the safety and stability of vessels, ensuring secure docking and anchoring. The manufacturing process involves careful selection of materials, advanced braiding techniques, and rigorous quality control to create a product that can withstand the toughest marine conditions. Eco-friendly innovations and international certifications further enhance the reliability and sustainability of these ropes. At Xinglun Rope Cable Co., Ltd, we pride ourselves on producing high-quality mooring ropes that offer superior performance and environmental sustainability.

For more information about our high-performance mooring ropes, please feel free to contact us. Our team is ready to assist you in selecting the perfect rope solution for your needs.